Solifos Supplies Sensor Cables for the Brenner Base Tunnel – the World’s Longest Railway Tunnel Project

The Brenner Base Tunnel (BBT) is one of the largest and most complex infrastructure projects in Europe. With a total length of 64 kilometers, the tunnel will be the centerpiece of the railway route between Munich and Verona, making it the longest underground rail connection in the world. This major construction project will not only transform cross-Alpine transport but also shift freight traffic from road to rail, contributing significantly to the reduction of CO2 emissions.

Challenges in Tunnel Construction: Ensuring Safety through Precise Monitoring

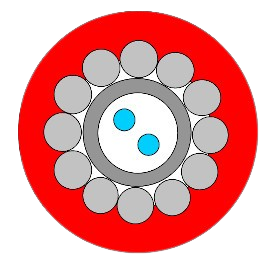

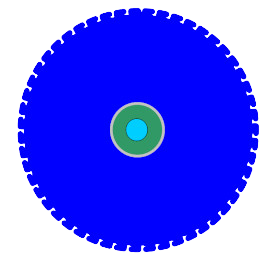

In a project of this scale, real-time monitoring and sensor technology play a crucial role. Especially in tunnel construction, the continuous monitoring of temperature and mechanical strain is essential for maintaining structural integrity and operational safety. As a leading provider of sensor cables, Solifos is supporting the Brenner Base Tunnel project by supplying highly specialized fiber optic cables for Distributed Temperature Sensing (DTS) and Distributed Strain Sensing (DSS). This is in collaboration with ACI Monitoring, who specialize in the installation of sensors in infrastructure projects.

Solifos Sensor Cables: Reliable Solutions for DSS and DTS in Tunnel Construction

DTS (Distributed Temperature Sensing) and DSS (Distributed Strain Sensing) are among the most advanced technologies for monitoring tunnels and large-scale infrastructure projects. Solifos sensor cables offer key advantages in these areas:

- DTS (Distributed Temperature Sensing): This technology continuously monitors temperature along the entire tunnel length. Even minor temperature fluctuations, which could indicate overheating, fire risks, or equipment failures, are reliably detected. In long tunnels like the BBT, such precise monitoring is essential for ensuring a rapid response to potential hazards.

- DSS (Distributed Strain Sensing): DSS technology measures mechanical stress and deformations in the tunnel structure. By detecting shifts or structural weaknesses at an early stage, maintenance measures can be planned proactively and efficiently. This not only enhances safety but also reduces long-term maintenance costs and downtime.

Why Solifos Sensor Cables are the Ideal Solution for Complex Infrastructure Projects

Compared to traditional monitoring systems, fiber optic cables for DTS and DSS provide seamless and high-resolution monitoring. Instead of point-based measurements, Solifos sensor cables deliver continuous data across the entire length of the infrastructure—a significant advantage for complex tunnel construction projects. Additional benefits of fiber optic cables include:

- High Reliability: Fiber optic cables are resistant to electromagnetic interference and perform reliably even in challenging environments like underground tunnels.

- Durability and Low Maintenance: Solifos sensor cables are robust and require minimal maintenance, leading to significant reductions in long-term operational costs.

- Scalable Solutions: Our sensor cables can be flexibly integrated into various monitoring systems, offering customized solutions for every project requirement.

Innovation Meets Safety: Solifos in the Brenner Base Tunnel

The Brenner Base Tunnel is a flagship project for the future of mobility in Europe. Solifos’ sensor technology will play a crucial role in ensuring the tunnel’s operational safety and longevity. By combining DTS and DSS, our sensor cables enable precise and comprehensive monitoring, which is indispensable during both construction and long-term operations.

As experts in sensor technology, we are proud to contribute our expertise and solutions to this groundbreaking infrastructure project. Continuous monitoring through our sensor cables ensures that the Brenner Base Tunnel will be operated safely and efficiently—for decades to come.